The saga of DeLorean 06068 - Nissan VQ35 Engine Conversion

|

| The man himself, posing with John Z DeLorean |

It’s 2022 and I’m ready to tell the story of 06068

Doing the best that I can from memory. Even if I get some stuff wrong, I hope that it will be somewhat entertaining and interesting because I am asked about it often.

The 1990s

|

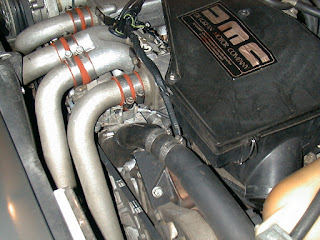

| Island Twin Turbo kit installed on stock PRV V6 |

It started in 1992 or 93 when I bought my 1st DeLorean. The previous owner had installed an Island Twin Turbo kit. At the time, I thought that was a good thing but turned out that it was not. After a few years of driving it, I realized that there was excess pressure in the crank case, especially at higher RPM. Twice, I had the pressure so high that the breather cap shot off the engine and dripped oil on to the hot turbo housing and ignited. Both times, I was able to put the fire out quickly and had no damage. It did, however, set me down the path to find the best way to have a faster than average DeLorean.

I spent months researching the options. The stock PRV-6 engine had high power cousins in Europe being used in Alpine and Venturi (not to mention, the Legend Industries Twin Turbo prototypes), but those parts were expensive and hard to find. It would also require rebuilding the engine with some of the "turbo" rated parts. The turbos themselves would also need to be reworked. I spent some time talking to John Lane who was pretty much the only guy doing hot-rod stuff for the PRV on this side of the planet. After all the time spent, I came up with a recipe for my engine, including parts from the 3.0L Eagle Premiere, European sourced parts, and even some totally custom parts. The estimated price was insane! And, not Crazy Eddie insane!

|

| Buick 3.8L Grand National engine |

My next idea was an engine swap. I had seen it done before. Bob Brandys completed a Rover V8 conversion and Duke Bladorn with a Chevy Vortec engine. Darryl Tinnerstet also had a Chevy swap and there was at least one Grand National swap running around. I am sure there are others I am forgetting, while none met my goals, they were inspiring.

Keep in mind, this is 1999. It was a different time for the Automobile industry. I very much wanted to keep it as light as possible, so the engine had to be aluminum. Also needed it to be <grunt> powerful, so I focused on 24V engines. At the time, my daily driver was a Taurus SHO and that was an influence too.

|

| Crysler 3.5L engine (stolen photo) |

The most powerful V6 engine I could find at the time (that was not exotic, something I could pick up at the local junkyard) was the Chrysler 3.5L. Aluminum, 24 Valve, 250HP in stock form. It was also used on the new Prowler, which added some coolness to it- "Yeah, I put a Prowler motor in my DeLorean". I also thought that the Prowler would be more popular and eventually have lots of after-market support. There was also the link between Chrysler and the PRV engine (it was used in the Dodge Monaco), meaningless but it felt like there was some heritage.

|

| Test fit of the Chrysler engine in DMC |

I had an engine, now what about a transmission? Interestingly, the 3.5L Chrysler engine was used in many front wheel drive cars (the LH series) but was mounted lateral (most FWD cars have transverse engines), so the 42LE transaxle was the same general layout as the DeLorean transmission with one big problem- it was backward. Having 4 reverse gears and one forward gear would not be all that useful. Reading up on the 42LE, I learned it had a chain drive that drove the differential which made me think- could I possibly replace it with a gear set that would spin the differential backward? I know I spoke to some people about this idea, and the details on why I abandoned the idea are fuzzy.

|

| Custom bell housing on the stock DMC trans |

Next, I considered an idea to make an adapter to mount the Chrysler engine to the stock DMC transmission. I discovered that the bolt pattern on the Chrysler 3.5 was the same as other older engines. I was able to source a flywheel from a Dodge Shadow and have it modified to work with the DeLorean clutch and pressure plate. I still needed an adapter or bell housing, for this I enlisted the help of a "professional" I used to work with at Bell Labs. He was a mechanical guy, and recently opened up his own design and fabrication business. I brought all the parts to him and said, "make it work". 5 years, and a few thousand dollars later I got back a pile of metal that sort-of resembles a bell housing.

The 2000s

By this time, I worked with Tom Sweeny at Bell Labs and another startup. I asked for his assistance in this project (and he agreed, not sure if he regrets that now!) and we staged everything out in my garage to see if it would bolt up. It did, but the custom steel bell housing was warped and would have torn the bolts out of the aluminum. OK, now what? The bell housing could not be leveled because there was no reference point to start with. It was also becoming apparent that I would have no support trying to get an ECU to run the Chrysler engine alone (without the other modules). Back to the drawing board. This is a good place to mention that the Prowler was discontinued by 2002. By the way, don't take stock tips from me.

|

| Tom Sweeney driving 6068 to DCS 2008 |

In the years that had passed, there were also changes in what engines I could choose from. I quickly focused on the Nissan VQ35DE. Back in 1999, it did not exist (well, not in the American market). The VQ35DE was used in the 2002 Maxima, 255 HP, all aluminum, 24 Valve (DOHC this time!), and cheap/easy to source. It hit all of the primary targets. It also had some very loose connection back to Renault with the 1999 alliance.

With my failed Chrysler attempt (let's call it a learning experience), I was better equipped to do further research and not make the same mistakes again. With my focus on the VQ35, I needed to find a transmission. Not a lot of options exist for a rear engine lateral mount setup. It is pretty much the stock DMC transmission, or the Porsche. Bob and Duke had already successfully used Porsche gearboxes, so at least I knew it would work. I easily found Kennedy Engineered Products (KEP) who made all sorts of adapters for different engines to mount to the Porsche 915 (and some Volkswagen) gear boxes. Major hurdle that was solved quickly.

How to make the engine run though? The Nissan cars that use the VQ35 were all "drive by wire", had variable intake cam timing, and other complex (for the time) computer controls. Unlike the Chrysler, the Nissans had a huge "tuner" following with lots of forums to learn from. I found that there was success in swapping the timing components from a VQ30 to the VQ35, and then I would be able to run the engine with the much simpler VQ30 ECU. Long story short, I was convinced I could make it work. Time to go shopping!

I bought a complete running VQ35 engine on Ebay for $475 (ah, the good old days!). I spent about $1000 for the rebuilt 915 Transmission (from a 1984 911, with a cooler!), another $700 for the KEP adapter. $1000 (est) in other assorted parts that were needed like the ECU, wire harness, Porsche shifter, etc. I lost track of it all but was happy to be well within my budget.

|

| VQ mounted in the DMC |

Tom and I got to work (after assembling his steel building to work in). After getting the engine and transmission bolted up with the KEP adapter, we spent many hours lining everything up with the goal of having the CV axles as straight as possible, which put the engine a bit further back than we would have liked. Once the position was set, Tom fabricated the mounts using a combination of DeLorean parts, Nissan parts, and Porsche parts. From there, we made a custom wire harness and converted the engine to run on the VQ30 ECU. After modifying the Porsche shift linkage, and (skipping over way too many details) we had a car we could take for a spin! Holy crap, it was a quick car!

The engine-swapped 6068 made its debut at the 2006 DeLorean Mid-Atlantic Spring Social (DMA). I gave some rides, got a few people to scream in fear (which was then dubbed the "the scream machine"), and overheated the brakes making me internally scream a bit! Mission accomplished! Yeah, like GWB on the deck of that ship...

|

| Unboxing the blower |

Best I can tell from my notes and emails, the real trouble started in 2007 when I began to shop for superchargers. I started to focus on the ProCharger units because I liked that they were mostly self-contained. No need for external oil feeds, etc. They were also compact and flexible to install. Sometime in 2009, I purchased a "slightly used" (claimed 15-20 hrs of use) ProCharger C2 on CraigsList. It showed up with a pipe welded to it, so it needed extensive "clean up" before it would be usable. Worst $600 I have ever spent!

The 2010s

|

| Fixing the poorly constructed Kenetix intake |

Winter of 2010, Tom and I embarked on installing the blower. It required relocating the alternator and modifying the intake. It was at this point I found a used Kenetix intake to help with the new plumbing and intercooler installation. I also chose an Infinity Q45 throttle body to be less restrictive. I sent my VQ30 ECU off to Jim Wolf Technology (JWT) to be modified so the fuel maps could be set up for boost, and use the 555 injectors I also sourced from JWT. The Nissan fuel pressure regulator was replaced with an aftermarket adjustable one.

|

| Working on the blower install |

Tom and I spent almost as many hours installing the blower as we did on the initial conversion, all while starting to increase the number of customer cars coming in to Tom's Garage. We were spending so much time in the shop that the name of 6068 seemed to change from "Scream Machine" to "Widow Maker". The car was back on the road by the spring, and while the fuel still needed some tuning- it was very quick.

But that did not last long... On an unplanned trip to a car show at Raceway Park (drag strip), participants were given the opportunity to take a run down the 1/4 mile track. Time to see what it could do! Well, what it could do was start blowing oil out of the tailpipe 3/4 of the way down the strip. Something broke, likely a ring or maybe even a cracked piston. It was a short and embarrassing ride home, but I made it.

|

| Nissan flexplate washer Not needed with KEP Flywheel |

August 2010, I bought my 2nd engine: $1200. It was an amazing jump in price for only 5 years. We pulled the broken engine, and stuffed it under a workbench. While installing the replacement, the flywheel to crankshaft bolt heads looked damaged - it was obvious that the bolts were rubbing against the clutch. Apparently that washer that was on the original Nissan flex plate should NOT have been used with the KEP flywheel. Who knew? There were no instructions. We installed the new engine in the car without the extra washer, and moved all of the VQ30 timing components and accessories to the new engine. That wasn't so bad, right? Wrong.

|

| Bolt heads damaged the clutch springs |

We immediately discovered that the entire car would have a violent vibration when releasing the clutch (especially in 1st gear). It became very hard to drive. We dropped the transmission, pulled the flywheel and associated components, and had it all checked out at a machine shop. Got a fresh resurface, and a clean bill of health. It was all put back together with no improvement. I drove the car for the rest of the season while trying to research how to proceed with the vibration.

Sometime in 2011, the transmission blew up. Odd, since it was "rebuilt"- but can we really trust random people on Ebay? Maybe the vibration was a precursor to the destruction? Researching what to do next, I found that Gary Fairbanks, known for his work on the Porsche 915 transmissions, was not that far from me. We arranged a meeting at a diner in Connecticut off Rt 95, and I gave him the transmission to rebuild. So, this is the point in time where I stop discussing how much I am spending because it gets insane, and somewhat embarrassing. A few weeks later, I pick up the rebuilt transmission (let's call it #2) and proceed to install it back in the car. It runs nicely, but still has that vibration!

Late 2011, the engine started to make an awful noise that sounded like bad bearings. Engine #2 was purchased with "less than 20K mile", but can we trust junkyards?? In hopes of saving it, I dropped the oil pan and replaced the Rod, Main and Thrust bearings in the car.

|

| Engine #2 rod smashed oil pan |

In 2012, I tried to focus on getting a good fuel map. It seemed like I was driving everywhere with a laptop to collect logs and sending them to JWT to then program new chips for me to try. With the new bearings, I was starting to notice low oil pressure and the engine was starting to make noise again. Time to start shopping for engine #3. I found one in Florida, and my friend Ken Koncelik of DeLorean Car Show fame happened to be driving up for the DMA spring event. He picked up the engine for me, and brought it up- just in time.. Since I already had Engine #3, why not take it back to the track? The DMA spring event had a Friday night gathering at Island Speedway (drag strip)- so, let's see what it can do (again!). I think it was the end of the 2nd or 3rd run, the engine was making an unbelievable racket, so I decided that was it- time to head out. about 5 miles from the track, while passing through Hacketstown, BANG! And, that was the end of Engine #2.

|

| Engine #3 in Ken's "mighty" truck |

Within a week, I was already starting the process again and swapping the engine. By now, we were experts at it! Last step before starting it, change the oil- which should have been the 1st step, because there was sand in it! With nothing to lose, the oil was changed, and I started driving it again, still with the awful vibration when releasing the clutch. I was already shopping for Engine #4.. Do I even have to say it? The engine blew within the month.

It was still early in 2012 (May!), and I was driving to a junkyard in Philadelphia to pick up another "low mileage" VQ engine. Did the swap, and while installing the VQ30 timing components saw that the inside of the engine was awful. Clearly there were more miles on this than I was told, and it looked like the oil was never changed. After getting it reassembled, we did a compression test. Eh, this one was not even worth trying and we pulled it back out without ever running it.

|

| Fourth VQ35 engine |

The car was drivable and making it to the various DeLorean events and such but still had that awful vibration and I was still trying to get the fuel map right- it always ran too rich. It was running well enough to "show off" to a customer who stopped by Tom's Garage one weekend in the late spring of 2013, and that is when I lost the Transmission again (Let's call it #3, even though it is the same as #1 and #2, but rebuilt). Another trip to see Gary Fairbanks!

|

| Some of the damage to Trans 2 |

Gary and I discussed the vibration at length, and he said he would double check everything to make sure the transmission was not the cause of it. I did not think it was, but it never hurts to check it again. If anything, I was thinking the vibration is what killed the transmission twice in such a short period of time.

By this time, Tom Neiland had completed his Acura engine swap on a DeLorean and also chose a 915 transmission. He built his transmission mounts a bit differently than we did. His was much sturdier and made better use of the Porsche mounts where our original design modified the stock DeLorean mounts. Best form of flattery is to plagiarize?? With Tom's permission, we duplicated his design in hope of fixing the vibration issue. While it did improve on the stiffness of the assembly, and the ability to shift, the vibration remained.

|

| Our 1st try at the Trans mount |

I (stupidly) kept putting the vibration issue on the back burner and focused on trying to get the fuel right, there were ECU issues, sensor issues (MAF sensors don't like boost), electrical issues, and of course the fuel map itself. I continued to drive the car for over a year, while trying to sort it all out.

|

| Tom Neiland Acura Transmission Mount |

10 years had passed since the swap was done and technology had improved. I happened to be watching one of those "reality" car shows on basic cable, and they were building a custom car using a VQ35 engine. One of the mechanics seemed to rig up a stock Nissan ECU from the VQ35 to run the engine without all of the other modules. This got me thinking I should try and restore my VQ35 engine to its former glory with the biggest difference being the variable intake cam control. Maybe a different ECU would help me solve my fuel problem too.

I had been following the MegaSquirt project since 2005 because I considered it at the time (even for the Chrysler), but it was not mature enough. In 2010 the MS3 came out, and it seemed to have all that was needed to run the VQ35. While I had been keeping up with it, and even had some email exchanges with Matt Craner over at DIYAutoTune, I was starting to think seriously about making the switch. Going with the stock Nissan ECU was still not in widespread use, while the MS3 clearly had built up a large following and support network. Winter of 2014, the MS3 install began.

While all of this was going on, Tom and I were keeping very busy with other cars. We did a full frame-off restoration for a customer and had the pleasure of working on John Dore's DMC-24 (4 seat DeLorean - you can see us at 2:50 on the video). As shop businesses increased, it gave us less time to work on our own stuff.

|

| Working on the DMC-24 frame |

Along with this significant upgrade of variable cam timing using the MS3, I wanted to improve the air flow through the intercooler and intake. It was a goal for the supercharger to be more "stealthy". The intercooler was always the giveaway that had spectators looking for the source of boost. Since all of the engine wiring was going to be redone, it was also a great time to clean up the ugly wires, including what was left over from the original PRV. Lots of parts and hardware ordered, new wiring harness hand made by Tom and me, while John Dore would fiberglass over all of the holes for the original wiring to have a much cleaner look.

|

| Ready to remove the VQ30 timing |

The software in the MS3 had the proper coding for the original Nissan VQ35de signals, so it eliminated the need to install external sensors for crank and cam position. I did however need to have the tooth wheel changed from the VQ30 style to the VQ35 style, and KEP said it would be no problem. I also asked them about the ongoing vibration issue, and they asked that I send them the flywheel, clutch, and pressure plate so they could check everything.

|

| Installing VQ35 parts |

KEP suggested I replace the clutch setup with one of theirs even though they did not find anything specifically wrong with my setup. I really did not want to do it all again and needed to fix the vibration that had already claimed 2 engines and 2 transmissions, so I agreed. They swapped the sensor ring, resurface the flywheel, and sold me on all new parts including all new bolts. Hopefully this would be the end of buying parts.

|

| Working on the new VQ35 intake |

It also explained why the vibration appeared after Engine #1 was installed, because the Nissan washer was removed, and the bolts bottomed out instead of being tight. All of this time, the flywheel was not seated against the crankshaft. I asked KEP about this, but they did not respond. Now, I was very excited to get the car running again so I could shift without that vibration.

|

| Another day working on the VQ35 |

Sometime late 2017, we discovered that the timing ring on the flywheel was totally in the wrong spot. To confirm, we dropped the transmission and removed it all and laid it on top of a stock Nissan flex plate. Yup, way off. Shipped back to KEP November 2017 to be fixed. We reassembled everything, ready for that VROOM.

|

| Comparing the KEP flywheel to stock flexplate |

|

| Getting the ECU wired |

|

| Porsche starter ring is shot |

While that discussion was going on, it was still apparent that the sensor signals did not match what we expected to see according to the Nissan factory manual, so I decided to check all the mechanicals one last time and found that the primary timing chain tensioner was seized up and there was a bit too much play in the chain. Fixing that again improved the situation, it would start much more reliably. I thought I had the problem fixed and could get back to tuning. It was starting reliably enough that I continued to work with Matt for the next year on various aspects of tuning. Again- Matt is amazingly patient and helpful.

While I continued to tune as I had time (not all that frequently) it really started to bother me that the oil pressure gauge on the dashboard would read VERY low once the engine was hot. The low oil light never came on, but it was giving me flashbacks to the low oil pressure on Engine #2 right before it exploded. I brought this up with Darren Surratt from NISformance (He had been consulting with me on a number of Nissan questions I had over the years- Also very helpful), and he mentioned that the VQ35 engines had a known issue where the oil gallery gaskets in the rear timing cover would rip, and oil would leak out. On a stock Nissan ECU it would set off a Check Engine light because the variable cam timing would fail to work, but I did not have that with the MS3.

The 2020s

Tom and I got very busy with other work, so time for 6068 became hard to find, but in September 2020 I started to disassemble the engine again to replace those oil gallery gaskets. To get the front timing cover off, the lower oil pan has to be removed. Good thing too, apparently at some point two of the four thrust bearings dropped out of the engine (again! Engine #2 flashbacks!), I am very much hoping this is a remnant of the vibration that has since been fixed with the proper flywheel bolts. Plus, I busted the upper oil pan while taking it apart. More parts to order.

Again, while working on other things trying to find VQ time, I got the engine back together late 2021 (COVID slowed things down too). I replaced every oil seal and gasket and replaced all of the lower engine bearings (Main, Rod, Thrust). Hoping so much this was going to be the end to the ongoing headaches, I turned the key, and it started. I let it run for a while, and again the oil pressure started to drop. Shut it down and was unable to restart it. The MS3 would not sync up. Tom and I repeated this a number of times for a few weeks, repeatedly checking the timing chain was correct, the tensioner was working, etc. We theorized that maybe the low oil pressure and sync issue were linked, and hooked up a mechanical oil gauge which told us even though the dashboard was showing very low pressure, we were still in factory spec. Back to emails between Matt, Ben, Clark, and now Brett.

Brett suggested we check to make sure the alignment pins on the engine were in place because if they were missing It may cause alignment issues with the starter and the crank sensor. There was hope to fix both problems at once, but that was a dead end as both pins were in place. It would make sense that the problems are linked, but this was not the link.

I returned to focusing on the timing issue, even using some clay to take an imprint of the notch in the timing ring at TDC. I noticed it was not in the center, as it should have been but for some reason ignored that detail for a while, bouncing between both problems (and working on other stuff).

|

| Imprint of tooth in clay |

Consulting again with "the gang" of Matt, Ben, Clark, Darren, and Brett separately, I started to ask about the placement of the tooth ring on the KEP flywheel. Brett confirmed that his research came back with a number of different clock positions as well as heights for the various flavors of VQ35DE engines, making it likely that having it drilled for the RWD would not work for FWD even though I moved it. Time to pull it all apart again and send the flywheel back to KEP. That flywheel has more miles on it than the car! Unfortunately, it got a clean bill of health from Brett. He said the timing marks are within 1/2 degree of what they expect it to be.

2025 Update

The summer of 2022, I escalated this issue with DIY Autotune up to the owner of the company (Jerry). After some heated discussions, we managed to de-escalate, and he got in touch with their software developer (James) and asked to look at the timing code. Part of the conversation got moved to the public forums and are available to anyone interested, but the short version of the story is James agreed the timing code was wrong based on the information in the Nissan factory service manual - which matches what I was seeing on the oscilloscope from my engine. Within 48 hours, new "test code" was made available to me. With the new code, the engine started! No more backfires, or starter hesitation, etc. While I am thankful to Jerry and James for resolving the issue, I can't help but be angry about all of the time and money wasted due to a defective product. No apology or compensation was offered.

Time for the first drive with the new setup, and amazingly the vibration issue was gone! The conclusion was the bolts provided by KEP were too long, and that was the root cause. Again, no apology or compensation was offered.

I got the car back home from the shop, and it has not moved much since. Engine has been started a few times, and I messed with the cold fuel settings to try and get it to start more easily, took if for a few very short rides, and that's it. While I am pleased that the two major vendor created roadblocks have been fixed, I am still running with an engine that has some damage from the vibration (who knows when those bearings will fall out again, or maybe they already have?), still seeing what I think is low oil pressure when the engine is warm.

Spent the last year doing some much needed maintenance on 1860. The VQ35 engine still needs some serious tuning, but at this point I make the excuse that I don't have the time to work on it. The reality maybe I am afraid to drive it and have something fail again.

Be sure to check out this webpage that a "fan" made without my knowledge. my4dsc.com

|

| The End?? |